Whisky is a valued and versatilely distilled alcoholic drink. It is appreciated for its very rich and interesting history by most whisky enthusiasts and drink experts. Whisky tops the charts When it comes to a fine blend of character, flavors, and depth. When it further comes to its production, it requires proper planning, carefully selected ingredients, controlled processing, top-tier machines, excellent craftsmanship, and a touch of nature.

Ingredients Used in Whisky Production

Whisky production cannot exist without quality and carefully picked ingredients. They are the major determinants of how flavored and spirited the whisky is going to turn out. The primary ingredients used in whisky production include the following:

Grains:

Grains are the key source of fermentable sugar, and the type of grain used determines the classes of whisky to be produced. There are various grain types used to produce whisky, and they include:

Barley

Corn

Rye

Wheat

Water:

Water is the next key ingredient required to get the best of the character of the spirit. Clean water is needed with utmost importance from the first batch process of production to the last. Interestingly, water contributes to the distinct qualities contained in the whisky.

Yeast:

When it comes to fermentation, yeast is the go-to ingredient for making whisky. While yeast converts raw grain sugar to carbon dioxide and alcohol, it can also affect the flavor and aroma of the whisky.

Peat:

It is an optional ingredient, but it is also useful. It helps to provide a kind of smoky flavor especially distinct for a certain kind of whisky.

Whisky Production Techniques

Producing whisky is an interesting journey, as each process is vital. Depending on how is whisky made, the quality and desired flavors, creative and innovative methods can be introduced. Here are the key whisky production processes:

Malting

Malting, as a key process, involves the preparation of the grains for fermentation. Interestingly, the main aim of the malting process is the generation of malted barley, fermented cereal grain, which is a needed ingredient for the production of distilled alcoholic beverages and malt whisky.

The malting process begins with the selection of top-tier barley grains of quality. They are handpicked based on the required qualities such as flavor, starch content, and enzymes. Interestingly, they affect the whisky’s aroma, taste, and quality. After the selection of the chosen barley grains, the unwanted parts are removed, and the purified ones are stored in steeping tanks. The steeping tanks are large containers that are used to soak the barley in water to keep the grains hydrated.

When the barley grains are properly hydrated, they are moved to the allocated germination boxes for proper air control. The barley grains begin to sprout after they are cut into thin layers in the form of a single malt of bed. The enzymes I’d the grains are promoted when the germination process begins.

The next step is converting starch and activating enzymes, which is crucial for the fermentation process. During the course of germination, attention must be paid to the growing grains to endure that the required sugar conversion is achieved. Also, it can be easily done by watching and regulating the humidity, temperature, and light. Once the required level of germination has been attained, the malted barley is dried by hot air in a malt kiln to preserve the already converted sugar. Next, after the kilning process, is the cooling and storing of the malted whole grain mash or barley.

Mashing

When the malting process is over, the next required technique is the mashing process. Mashing deals with the production of a liquid sugar called wort from malted barley. The wort is of utmost importance in the fermentation stage. Hence, mashing helps to bring out the required fermentable sugar in order to produce the yeast needed to turn the malted barley into alcohol.

The malted barley is ground into powder, popularly called grist. During the grounding of the malted barley, the starchy interior is exposed. Care is taken during the grounding not to disrupt the starch extraction from the grains. After getting the grist, it is mixed with hot water at a high temperature in the mash tun. The hot water and grist are combinational and are stirred till it forms a proper mixture. The mixture goes through a lot of other essential processes, such as regulated resting, to allow the enzymes to break down the complex started into smaller required forms.

After the rest and other activities, the mixture, called a mash, goes through the mash-out process, which provides for easy separation of the wort from the draft. The end result in the mash bill, the form of wort, is finally composed of the fermented and converted sugars, thus ready for the fermentation process.

Fermentation

Fermentation is the determinant of the whisky’s overall turnout at the production process’s end. It involves the use of yeast to turn the resulting liquid sugar work into carbon dioxide and alcohol. The alcoholic base created by fermentation is the core of the whisky.

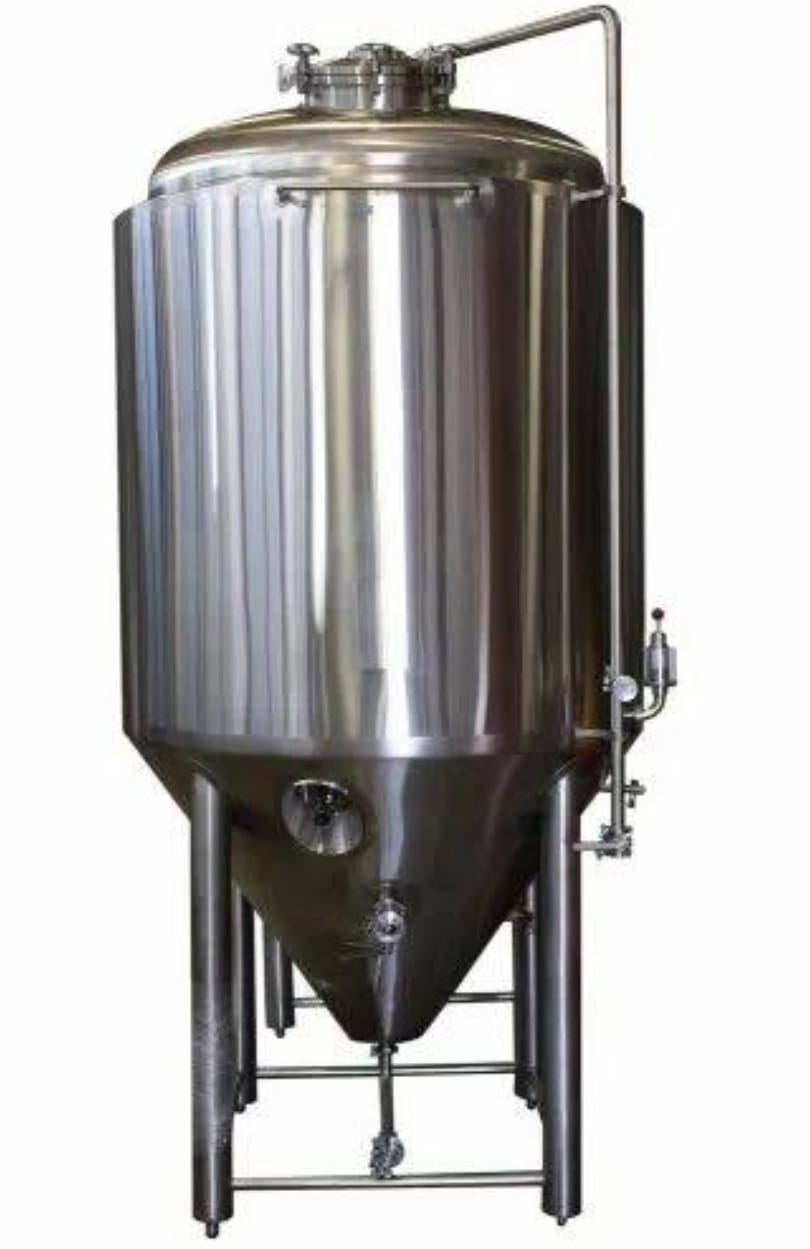

The sugary liquid wort is transferred into washbacks known as fermentation vessels. Interestingly, the type of washback used has a subtle influence on the whisky in the long run. Yeast is added to work in order to get alcohol and carbon dioxide. There are various strains of yeast added, which add distinct flavors to the whisky. After the introduction of the yeast, the contents must be stirred properly to allow for even distribution and blending of the yeast and the wort.

With the sugary wort feeding the cells of the yeast, it gets energy for its survival by converting the sugar into alcohol and carbon dioxide. Carbon dioxide can be noticed via the bubbles it produces, thus showing active fermentation. In order to get a unique flavor or quality, the temperature during the fermentation can be regulated. Interestingly, higher temperature provides a fruity whisky twist, while lower temperature provides a delicate and clean whisky twist.

The required duration for the fermentation process differs, with the minimum being 48 hours and the maximum running into several days. The duration of the fermentation is the core of the flavor of the whisky. To get a more layered and detailed flavor of whisky, the fermentation period should be longer. The end result of the fermentation process is a liquid containing yeast cells, alcohol, sugar remnants, and other results of the fermentation process.

Distillation

Distillation is the next key process in whisky production. It involves refining the fermented grain wash into a new spirit. The main procedure is to separate water from alcohol. The benefit of the distillation process cannot be overemphasized, as it affects the aroma, flavor, and characteristics of the whisky. There are two rounds of the distillation process, which include wash and spirit distillation.

Wash Distillation

The wash distillation is the first round of distillation in the journey to getting the whisky. The wash from the fermentation process is put in a copper-made pot. The copper pot is best suited for the heating process as it allows for proper refinement with hot steam. The heated pot allows for proper distribution of the temperature. Once the alcohol boils, the wash is boiled, and the alcohol with its lower boiling point vaporizes first till it gets to a condensation point.

During the condensation process, the alcohol vapor cools down, turns back into a liquid form, and the resulting liquid is collected into a vessel. The collected alcohol is called raw spirit or low wines, and it has higher alcohol content and other important and nonimportant elements. The raw spirit is not perfect. Hence it will undergo a further refinement process.

Spirit Distillation

The second round of distillation is spirit distillation, which comes after the wash distillation. The raw wine or low spirit is heated in a few pot stills to the point that the whole alcohol evaporates, boils, evaporates, vaporizes, and condenses into several fractions. The unique fractions of the alcohol are distilled continuously and are collected in different stages.

The unique fractions are known as head, heart, and tail, and they are identified by their optimal boiling points. The heads contain compounds with Lower boiling points. The heart contains the concentrated alcohol area, which also has more flavors. The hearsay also provides for top-quality distilled spirits throughout. The tails, on the other hand, contain compounds with higher boiling points, which in turn, produce the rich oily flavors that are found in the traditional spirit made.

The required quality needed for the rye whiskey also determines the precise cuts to be made. Interestingly, spirit distillation provides rye whiskey with a higher alcohol content. The newly produced spirit serves as the core of the whisky maturation.

Maturation

The next process is the maturation process, popularly known as “aging.” This process determines a lot from the taste, aroma, and quality of the production of whisky. Maturation refers to the filing of the newly distilled spirit into oak barrels for storage for long durations. By the time the whisky blends with the used oak casks, there are vital chemical reactions that will affect the quality of the whisky. For efficiency, the oak and wood barrels used must be carefully selected to suit the desired whisky flavor. The wooden and charred oak barrels also must be done in a way to prevent air contact to prevent oxidation.

Interestingly, the spirits can be diluted before the filling of white oak barrels or wooden casks so that the aging process can occur naturally and quickly based on the extraction and evaporation. The oak barrels, sherry casks, or wooden casks then are taken to storage areas which must be conducive for the whisky. The necessary conditions include humidity, temperature, light, and ventilation. The area and the vital conditions have a significant and vital impact on the final results of the whisky production.

The best location for storage location must have the best refinement requirements. The climate also plays a vital role, as warmer climates provide for faster aging. At the same time, cooler climates provide for slower aging as it affects its development. Interestingly, barrel positioning is also key such as near walls or floor areas inside the warehouse. Positions provide for unique aging variations.

There are aging durations suitable for each flavor of whisky. Short aging is between 3 to 5 years, and it provides for slightly raw, fresher, lighter and softer flavors. It usually contains fewer oak-derived flavors as it does not interact well with aroma compounds in the oak barrels. The medium aging duration is 6 to 12 years, and it provides for a more balanced and enhanced flavor. There is an improved oak-derived flavor as part of the whisky.

The medium-aged whisky also provides a fruity taste. The long aging process is usually 15 years or more, and it provides for distinct multilayered and complex flavors due to the extended period the whisky spends in maturation. There is also a more prominent oak-flavored taste as it becomes well-integrated with the oak barrel. It also has a better mouthfeel, smooth and refined taste. However, there is also a risk of the whisky becoming over-oaked and bitter due to too much presence of oak.

Bottling

The final stage in the production of whisky is the bottling process. A proper bottling process is vital to preserve the quality of the matured whisky. Before the bottling process begins, the well-aged whisky must first be aged and undergo all the required steps. The whisky should undergo either chill or nonchill kind of filtration.

The chill filtration is to cool down the whisky via low temperature and a filter. The chill filter helps malt whisky to get rid of impurities, while your non-chill filtration helps single malt whiskey to sustain the presence of essential natural oils and other compounds. If necessary, there may be a blending process involved. Interestingly, the whisky can be diluted in other to adjust the bottling strength of the whisky.

When the whisky is ready and set for bottling, the bottles are cleaned and measured. The measurements are to help ensure that the volume of the whisky matches the capacity of the bottle. The bottling process may be automated via machine-controlled bottling lines or done manually. The scale of production depends on the bottling process. After bottling the whisky, it is vital for the bottle to be labeled with all the essential information.

Types of Whisky

There are various variants of whisky, but here are the popular whiskies:

Scotch whisky:

The scotch whisky is made from malted barley. The scotch whisky maturation period is a minimum of three years. The three main types of scotch whisky produced are single malt scotch, single grain, and blended. The main geographic producers of single grain whiskies, single malt scotch, and single malt whisky are in Scotland. Hence, the whisky boasts sophistication, rich history, and high standards.

Irish Whisky

The Irish whisky is from Ireland and is made from a fine blend of unmalted and malted barley. Irish whisky should be aged for a minimum of three years in wooden or oak casks. It helps provide the whisky with a smooth, fruity, versatile, and light texture and taste. The three primary variants of Irish whisky are single malt whiskey and pot stills, blended Irish, and single malt whisky.

Canadian Whisky

The popular name for Canadian whisky is “rye whisky,” which its origin in Canada. Canadian whisky is made from a combination of whiskey types of grains and must be aged for a minimum of 3 years in a wooden barrel. The Canadian whisky has a smooth texture and a prominent rye influence in the taste.

Japanese Whisky

Japanese whisky is processed from malted barley, and it is known for its refined and delicate appeal to the taste buds. The oak barrels are used for the maturation process of corn whiskey as well as an adequate aging period. Interestingly, Japanese whisky goes through a seamless blending process to make it into a fine and elegant drink.

Indian Whisky

Indian whisky is made from a combination of different grains and molasses. The determining measurements are dependent on the proposed amount as much sugar and flavor to be gotten. The Indian whisky has a sweet and fruity taste, thus giving it tropical or spicy vibes. The climate in India favors the maturation and aging process of the whisky, hence the increase in the flavor.

Australian Whisky

The unique Australian whisky is made from various grains, which are then aged in wooden barrels and pot stills for a lesser maturation date. This is a result of the climate of Australia that provides for rapid maturation. Australian whisky is known for its unique and distinct flavor profiles. The flavor profiles range from tropical fruity flavor to smokey flavor, especially when peat is used.

American Whisky

The American whisky is made from a combination of various grains. The whisky can be aged for a few years or more but must be done in new charred oak barrels. American whisky boasts a wide range of flavors and textures appealing to the different taste palettes of whisky enthusiasts.